Customized Conveyor Solutions

SparTek provides a wide variety of conveyor solutions.

Automating the transfer and shuttling of individual panels or stacks is part of almost every project we do. SparTek can design a broad range of innovative conveyance systems to support your automation strategy.

Rubber Mat Stacker

To eliminate the current standard procedure of mats being manually palletized and stacked, SparTek Industries has designed an automated mat stacker.

This upgrade provides an effective utilization of labor and reduces the risk of repetitive motion injuries. The automated mat stacker will accept mats off the outfeed of a finishing clipper and stacks them on a pallet.

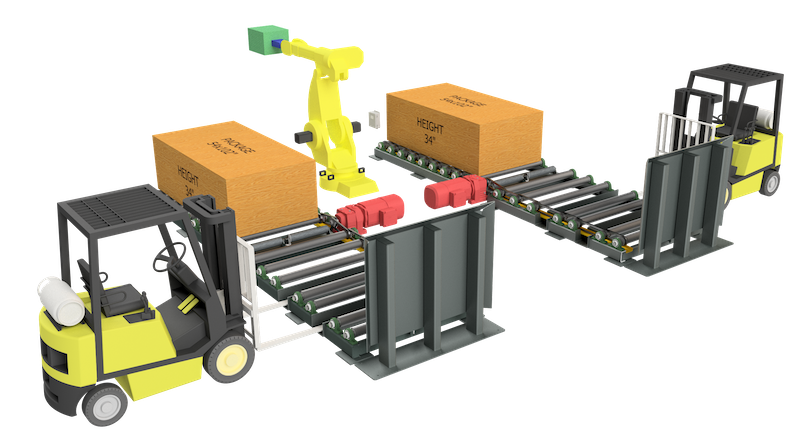

Panel Stacker & Side Shift

This high production panel stacker uses two primary carriages with four or five forks in each to lift and carry the panels to the accumulator lift.

The stacker positions them to be lifted and stacked by the alternating carriages. A servo motor drives the forks in each carriage for smooth acceleration and positioning control. This is a turn-key system and only requires a few handshake signals from the layup line for automatic operation.

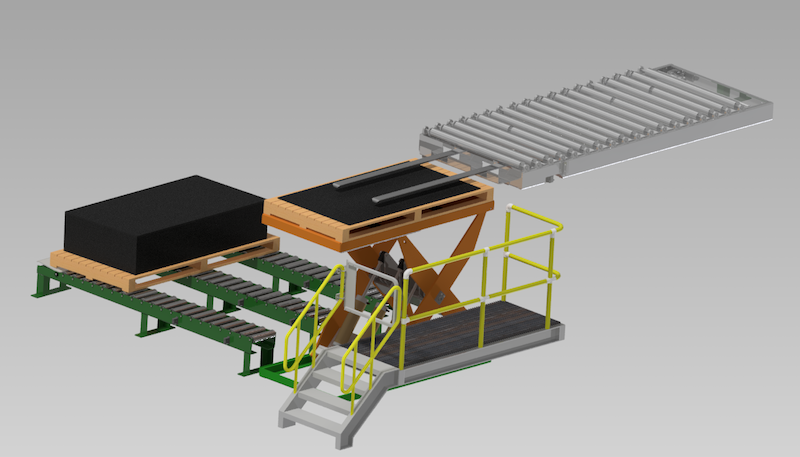

X-Lift

An X-Lift or Hydraulic Lift, is a flat panel device which helps lifting, dragging, and carrying heavy or large palettes from one location to another.

It helps save user’s energy and prevents injury in action. It employs a hydraulic system for elevating and lowering. The X-Lift can support the load from 100 up to 100,000 pounds and can be designed for individual user’s application.