Finding solutions to efficiently lift, drop, and roll products through your press line is a fundamental part of SparTek’s strategy to improve the efficiency and profitability of your manufacturing process.

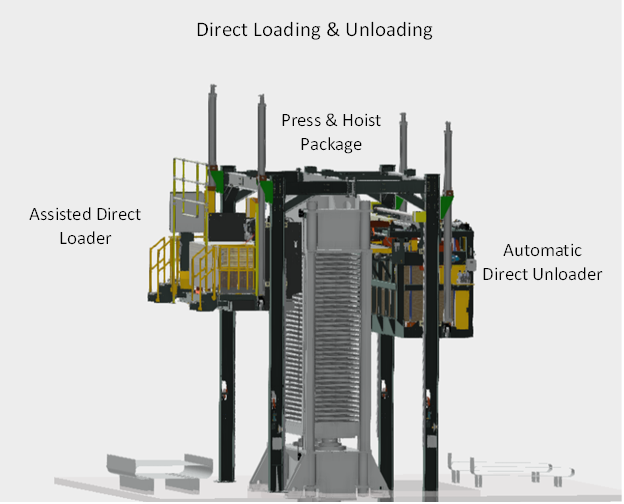

Direct vs. Staged Loading/Unloading

Direct Method – Smaller Footprint

- Direct Loader (assisted or automatic) indexes down the infeed side of the open press loading each opening.

- Unloaders automatically "follow" the direct loader receiving the pressed panel as each opening is loaded.

- Press closes to begin pressing cycle, next stack shuttles from pre-press to loader.

- Press opens at end of cycle.

- Once the press is empty the unloader moves the pressed stack down and shuttles the panels to trim saw.

- Process repeats.

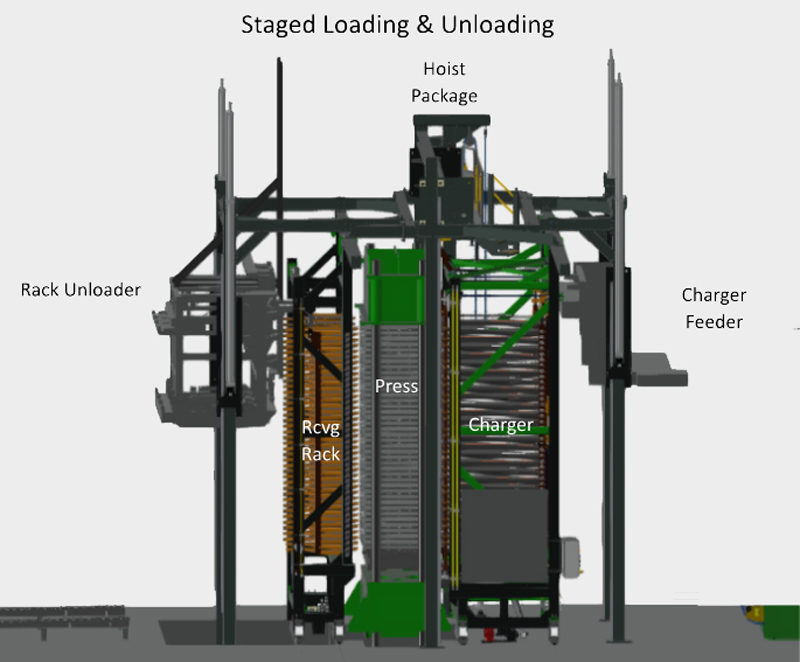

Direct vs. Staged Loading/Unloading

Staged Method – More Press Cycles Per Hour

- Press closes to “bake” current load of panels.

- Charger feeder moves to the top of the charger and travels downward loading each charger opening, receives and holds the next stack from the pre-press.

- Rack unloader simultaneously begins unloading the receiving rack from the top down.

- When charger is full, charger feeder receives next stack from pre-press

- When the receiving rack is empty, unloader moves down and shuttles pressed panels to the trim saw.

- Press completes cycle and opens.

- All openings on the press are simultaneously loaded by the charger and pressed panels are simultaneously unloaded from the press.

- Process repeats.